How to Choose the Right Paper for Packaging

In packaging design and printing, the choice of paper directly affects the product’s texture, functionality, and cost control. With the wide variety of paper types available in the market, how can one make a professional and precise selection? This article will systematically analyze the characteristics of the seven most commonly used packaging papers and offer specific paper selection advice and practical tips, helping designers quickly make optimal choices in their actual work.

When selecting paper, the three core factors to consider are functionality, visual performance, and cost-effectiveness, all of which directly influence the final result.

Key Factors to Consider When Choosing Packaging Paper

Functionality:

- Weight-bearing Requirements: For heavy items, it’s recommended to use greyboard (1.5-3mm thick) or heavy-duty kraft paper (300-400g/m²) to ensure structural stability.

- Protection: For specific needs, such as oil resistance, use oil-resistant kraft paper; moisture protection can be achieved through lamination.

- Printing Quality: For high-precision images, use coated paper (157-300g/m²), which delivers vibrant colors and rich layers. Minimalistic designs work well with kraft paper, highlighting its natural texture.

Visual Performance:

- Glossiness: High-gloss finishes are best achieved with coated paper (double-sided coating), while matte textures can be achieved with embossed paper or kraft paper. Pearlescent paper is ideal for creative designs that require color-shifting effects at a 15° viewing angle.

- Color Reproduction: Coated paper offers up to 30% better color reproduction compared to regular paper. For dark-colored card stock, specialty inks are required to ensure accurate color results.

Cost-Effectiveness:

- Paper Type and Cost: Paper type directly affects cost, as the production process and raw materials can vary significantly. For example, coated paper is typically more expensive than regular kraft paper, and specialty papers (like pearlescent or art papers) cost more due to their complex manufacturing processes.

- Grammage and Thickness: The grammage and thickness of paper are positively correlated with cost. The higher the grammage and thickness, the more expensive the paper. For instance, 400g heavyweight kraft paper costs more than 200g standard kraft paper, but it offers better load-bearing and protective properties. Therefore, a balance must be struck based on specific needs.

1. Coated Paper (Glossy Paper)

Coated paper is one of the most commonly used premium printing papers in everyday life, such as for glossy magazines, promotional brochures, and luxury packaging. Despite its name, it has no relation to metal copper but instead refers to the special coating process on its surface.

Key Characteristics:

- Smooth Surface: The surface is exceptionally smooth, almost like a mirror, due to a coating made from kaolin clay and chemicals.

- Printing Quality: Coated paper offers vibrant colors and sharp images, and its smooth texture gives it a silky feel.

- Thickness Options: Coated paper is categorized based on its grammage (weight in grams per square meter):

- Light: 105g-128g (suitable for magazine pages)

- Medium: 157g-200g (ideal for catalog covers)

- Heavy: 250g-300g (perfect for high-end packaging)

Coated paper comes in two types:

- Single-Sided Coated Paper: Only the front is glossy, typically used for packaging boxes.

- Double-Sided Coated Paper: Both sides are glossy, suitable for brochures, shopping bags, etc.

Classic Example: High-end cosmetic boxes often use 250g double-coated paper with matte lamination to achieve a luxurious look while preventing fingerprints.

2. Kraft Paper

Kraft paper is commonly seen in daily life and is known for its durability. Despite its name, it is not made from animal leather but from wood pulp.

Key Characteristics:

- Natural Color: Typically light brown, although bleached versions are white.

- High Durability: Stronger and more tear-resistant than regular paper.

- Affordable and Eco-friendly: Made from natural materials, it’s biodegradable and safe for food packaging.

Common Types:

- Standard Kraft Paper: The common brown wrapping paper.

- White Kraft Paper: Bleached for a cleaner appearance.

- Heavy-Duty Kraft Paper: Suitable for packaging heavier items.

- Oil-Resistant Kraft Paper: Treated for food packaging.

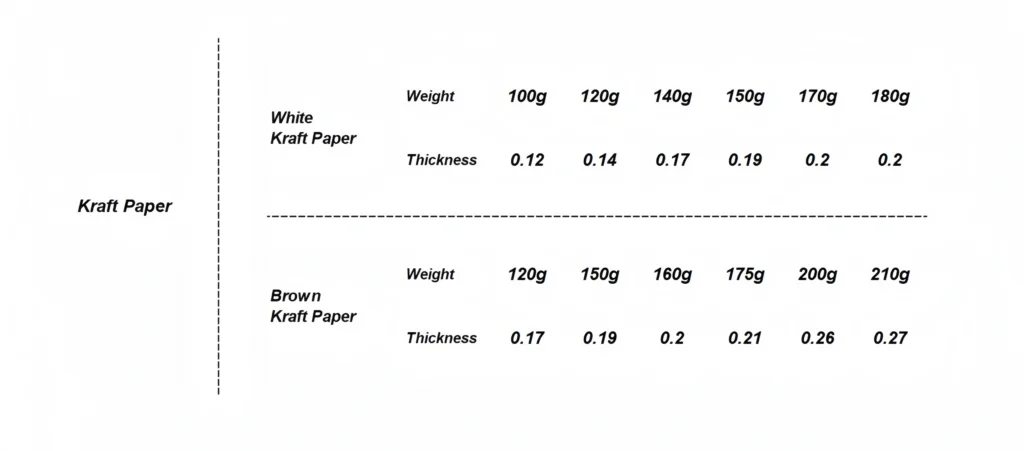

Thickness Options:

- Thin (60-120g): Ideal for packaging small items.

- Medium (120-200g): Most commonly used in everyday packaging.

- Heavy (200-400g): Best for heavy-duty packaging.

Popular Uses:

- Grocery bags, file folders, and food packaging.

- Eco-friendly and widely used for gift wrapping and custom DIY packaging.

3. Card Paper

Card paper is thicker than regular paper but thinner than cardboard, making it versatile for various uses.

Key Characteristics:

- Stiff and Smooth: Provides excellent printing quality and durability.

- Variety of Colors: Can be found in white, black, pearlized, or textured varieties.

- High-End Quality: It offers a premium tactile feel, making it ideal for luxury items.

Thickness Options:

- Light (200-250g): Suitable for postcards and bookmarks.

- Medium (250-300g): Ideal for greeting cards and name cards.

- Heavy (300-400g): Used for high-end packaging like invitations or gift boxes.

Popular Uses: Business cards, invitation cards, premium packaging, and gift tags.

4. Paperboard (Greyboard)

Greyboard is a strong, durable material commonly used in industrial applications. It is a reliable option for structural support in packaging.

Key Characteristics:

- High Durability: Often used as the core structure of rigid boxes or book covers.

- Affordable and Eco-friendly: Composed mainly of recycled materials.

Common Uses: Packaging boxes, book covers, display stands, and photo albums.

5. Tracing Paper

Tracing paper is semi-transparent and lightweight, making it ideal for use in artistic and design projects.

Key Characteristics:

- Transparency: It allows light to pass through, making it perfect for tracing and overlays.

- Smooth Surface: Offers a delicate touch and is often used for special effects.

Common Uses: Art projects, baking sheets, and special packaging applications.

6. Pearlescent Paper

Pearlescent paper has a beautiful shimmering effect and changes color depending on the angle of the light.

Key Characteristics:

- Shimmering Effect: Contains mica particles, giving it a pearlescent, iridescent effect.

- Luxury Appearance: Often used in high-end packaging and luxury stationery.

Common Uses: Luxury product packaging, greeting cards, and invitations.

7. Embossed Paper (Specialty Paper)

Embossed paper features a textured surface with raised patterns, offering a unique tactile experience.

Key Characteristics:

- Textured Surface: Raised patterns create an interesting tactile and visual effect.

- Elegance: Perfect for creating high-end designs and luxury branding.

Common Uses: Luxury gift packaging, business cards, and invitation cards.

How to Choose the Right Paper Grammage

Grammage refers to the weight of the paper per square meter (g/m²), and it directly affects the paper’s thickness and rigidity. For example, coated paper’s thickness can range from 0.09mm for 128g paper to 0.21mm for 300g paper. Understanding how different paper grammages and materials influence both the texture and cost of your packaging can help you make the right choice.

Typical Paper Combinations for Various Applications

- E-commerce Packaging: Greyboard (2mm) as the base, with 250g coated paper for aesthetic appeal and 120g tracing paper for product wrapping.

- Luxury Goods Packaging: Greyboard (3mm) for the structural base, combined with high-end embossed paper for a premium touch.

- Food Packaging: FDA-approved food-grade kraft paper for direct contact, with oil-resistant kraft paper for protection.

Future Trends in Packaging Paper

The packaging paper industry is undergoing revolutionary changes with the introduction of intelligent packaging, eco-friendly materials, and structural innovations. Some exciting developments include temperature-sensitive inks, plantable papers, and self-folding cardboard that eliminates the need for adhesives.

Conclusion

Choosing the right packaging paper is a strategic decision that affects product protection, brand image, and overall cost efficiency. By balancing functionality, visual appeal, and cost, brands can create packaging that looks premium while performing reliably.

Building a clear paper material database and conducting small-scale testing help identify the best options in terms of strength, appearance, and print quality before mass production. In the long run, thoughtful paper selection improves consistency, reduces risk, and ensures your packaging supports both brand value and operational efficiency.