Custom Rigid Boxes – Elevate Your Brand with Luxury Packaging

Fully Customizable Luxury Rigid Box Solutions – Choose from a wide range of sizes, shapes, materials, and finishes to create packaging that perfectly reflects your brand identity. Our custom rigid boxes are ideal for high-end products, luxury gifts, cosmetics, electronics, and fashion items, offering both premium presentation and durable protection.

The following are the brands we have collaborated with:

Personalized Rigid Gift Boxes – Uniquely Yours

Make every occasion special with personalized rigid gift boxes that speak from the heart. More than packaging, they are a statement of sophistication and thoughtfulness, perfect for weddings, birthdays, corporate gifting, and festive occasions.

Personalization: Add custom colors, names, and heartfelt messages to make your rigid box as special as the gift inside.

Customization Options: Choose from premium paperboard, luxury finishes (gloss, matte, soft-touch), foil stamping, embossing, and custom inserts to create a truly bespoke design.

Versatility: Ideal for fashion, jewelry, skincare, candle, or perfume packaging, our rigid boxes enhance every product presentation.

Design Expertise: Our professional team provides custom box design services, helping you bring your creative vision to life.

Our custom rigid packaging is where beauty meets functionality — elevate your gifting experience and leave a lasting impression with eco-friendly, luxury rigid boxes designed just for you.

Discover The Custom Rigid Box Style For Your Brand

Browse our range of customizable rigid boxes, designed to be fully tailored to your brand’s unique identity.

- Materials

- Printing technology

- Printing ink

Black cardboard paper

Black cardboard paper is a dense, sturdy paperboard with a deep black color, ideal for premium packaging, custom boxes, and luxury printing projects. Its strength and rich appearance make it perfect for high-end product packaging and presentation materials.

Kraft paper

Kraft paper is a sturdy, durable material made from unbleached wood pulp, naturally brown in color. Valued for its tear resistance and strength, it’s commonly used for paper creations, shopping bags, and wrapping materials. Eco-friendly and versatile, it remains a preferred choice for bespoke paper solutions.

Specialty paper

Specialty paper refers to unique, high-quality paper designed for luxury printing, invitations, high-end packaging, and art projects. It offers distinct textures, finishes, and surface effects, allowing brands to create exclusive and premium packaging experiences.

Corrugated paper

Corrugated paper is made by bonding a fluted layer (corrugating medium) between two flat linerboards, creating a strong, durable, and cushioned material. It is ideal for shipping boxes, protective packaging, and custom corrugated packaging solutions, providing both strength and product protection.

White kraft paper

White kraft paper is a durable and versatile paper made from wood pulp, featuring a natural, crisp white finish. Perfect for wrapping, folding designs, and premium paper products, it blends strength with a refined, upscale appearance.

White cardboard paper

White cardboard paper is a thick, durable paperboard commonly used for printing, packaging, and custom boxes. Available in matte and glossy finishes, it provides a premium appearance for product packaging, retail displays, and promotional materials.

Gold Hot stamping

Foil stamping is a printing technique that uses heat and pressure to apply metallic or pigmented foil onto a surface, creating a shiny, raised design.

Silver Foil

Silver foil stamping is a printing technique that applies a metallic silver foil to a surface using heat and pressure. This process creates a shiny, reflective finish, adding a sophisticated and elegant touch to printed materials.

Embossed

Embossed logo printing is a technique where a design or logo is raised above the surface of the material, creating a three-dimensional effect..

Pressure Texture

Pressure texture printing is a technique that uses pressure to create raised or recessed textures on a surface, often without the use of ink.

Spot UV

Spot UV printing is a finishing technique that applies a glossy, shiny coating to specific areas of a printed piece, creating a contrast with the matte background.

Debossed

Debossed logo printing is a technique where a design or logo is pressed into the material, creating a recessed or sunken effect. This process is achieved by applying pressure to the substrate, without ink, to create a tactile indentation.

CMYK

CMYK paper box printing is a process used to print full-color designs on paperboard packaging using the four primary ink colors: Cyan, Magenta, Yellow, and Key/Black. This method allows for vibrant, detailed, and high-quality graphics to be printed on boxes, making them ideal for product packaging. The CMYK process works by blending these colors in varying amounts to create a wide spectrum of hues, ensuring accurate reproduction of images and designs on packaging materials. It is commonly used for retail boxes, shipping boxes, and promotional packaging.

PANTONE

Pantone color paper box printing uses the Pantone Matching System (PMS) to produce precise, consistent colors for packaging. Unlike CMYK, which mixes four inks to create colors, Pantone printing uses specific pre-mixed inks to achieve exact shades. This method is ideal for brands that require exact color matching, such as logos and corporate colors. Pantone color printing on paper boxes ensures vibrant, consistent results across different print runs, making it popular for high-end packaging, luxury products, and branding materials.

Add Your Heading Text Here

Why Choose Our Custom Rigid Boxes?

Unmatched Quality & Durability:Crafted from premium, high-density paperboard and specialty materials, our luxury rigid boxes ensure long-lasting protection and a high-end look.

Limitless Customization & Design Flexibility:We offer complete customization — from box sizes, shapes, and materials (textured paper, velvet, recycled board) to printing options (CMYK, Pantone, foil stamping, UV coating, embossing) and inserts (foam, silk, molded pulp).

Superior Product Protection & Security:Our custom rigid packaging boxes safeguard your products during shipping, storage, and retail display, ensuring they arrive in perfect condition.

Elevated Brand Image & Unboxing Experience:Create a premium unboxing experience that strengthens brand recognition and customer loyalty — ideal for luxury brands, e-commerce, and corporate gifting.

Sustainable & Eco-Conscious Packaging:Choose eco-friendly rigid boxes made from recycled materials, FSC-certified paper, and soy-based inks, supporting your brand’s sustainability goals while reducing environmental impact.

Design the perfect custom rigid box packaging of your dreams

Custom rigid boxes are not only enhance product security and protection but also elevate the overall sense of elegance.

Select Style & Material

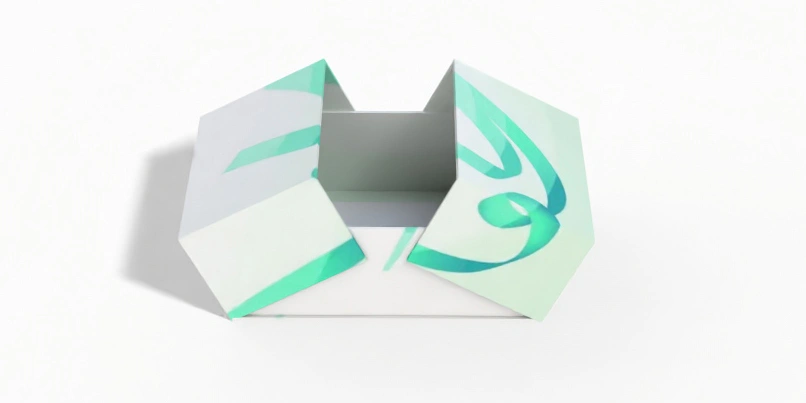

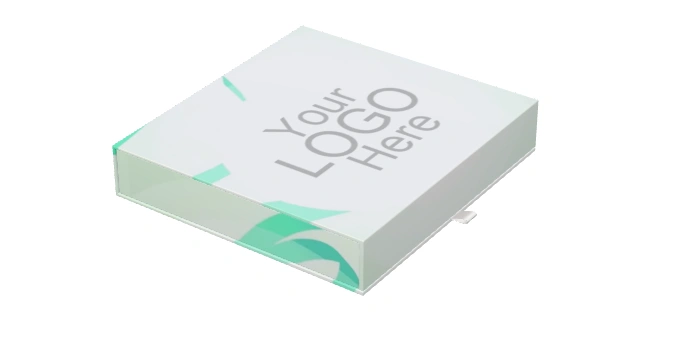

Start by selecting the rigid box style, size, color, and material that best fits your brand and product.Choose from magnetic closure boxes, two-piece rigid boxes, drawer-style boxes, or collapsible gift boxes, available in matte, gloss, or textured finishes.

Add Your Branding

Add a personal touch to your packaging with custom logos, foil stamping, embossing, debossing, or spot UV printing.Whether it’s for luxury fashion, cosmetics, jewelry, or gift packaging, our bespoke rigid boxes help you stand out and express your brand story.

Approve Your Design

Once your concept is ready, we provide detailed design or mockups for review .You’ll see exactly how your custom rigid box packaging will look before production begins — ensuring perfection in every detail.Our design team works closely with you to achieve the best structural integrity, and

Approve Your Design

After design approval, we begin precision production using advanced printing and cutting technology to ensure flawless quality.We confirm all production and delivery timelines, guaranteeing that your custom rigid gift boxes arrive on time, every time — ready to impress.

Frequently Asked Questions

Rigid boxes are typically made from high-quality paperboard, chipboard, or other durable materials. They can be covered with various finishes such as paper, fabric, leatherette, or even specialty coatings like foil stamping or embossing for added luxury.

Yes, rigid boxes are highly customizable. You can choose from a variety of styles, sizes, colors, and materials. Personalization options include custom logos, embossing, debossing, foil stamping, custom inserts, and more to create a unique look that aligns with your brand.

The MOQ for custom rigid boxes can vary depending on the manufacturer, but it generally ranges from 100 to 500 units. Larger orders may reduce the unit cost.

Many manufacturers offer eco-friendly options for rigid boxes, including using recyclable materials, soy-based inks, and other sustainable practices. Be sure to inquire about sustainable options when placing an order.

Rigid boxes are perfect for packaging luxury products such as jewelry, cosmetics, high-end electronics, gifts, and apparel. They provide a premium look and feel that enhances the perceived value of the product.

Yes, inserts such as foam, cardboard dividers, or custom molds can be added to rigid boxes to secure the contents and prevent damage. This is especially useful for delicate or high-end items.

Rigid boxes can be finished with a variety of options, including matte, gloss, satin, or textured lamination, embossing, debossing, foil stamping, and more. These finishes help elevate the appearance and feel of the box.

Production time varies depending on the complexity of the design and the order quantity. Typically, it takes 10 to 15 business days for custom rigid boxes to be produced after design approval. Delivery time will depend on your location and shipping method.

I got the boxes!! I am very satisfied with their service throughout the whole process. They have carefully arranged all things for me. We will definitely cooperate with each other next time. The quality of the boxes is good, and I believe it will be of great value for my packaging. Appreciate it, awsome!!! Thanks, my friend!!

Senior Manager

I had an amazing experiance with this supplier. They were attentive and promot to complete my project. They audited my draft for assurance there were no mistakes prior to final print. I highly suggest using thier services if you are looking for qualty materials and top customer service.

Packaging Buyer

The boxes we received were of excellent quality, meeting our expectations for durability and construction. The customer support team was very responsive and helpful throughout the process, addressing any questions we had promptly. Additionally, the price points offered were competitive, providing great value for the product. Overall, we are satisfied with the purchase.

Global Sourcing Manager

Ready to Create Your Custom Rigid Boxes?

Contact Us Today for a Free Consultation and Quote