Custom Printed Shipping Packaging – Durable & Sustainable

Fully Customizable Packaging Solutions

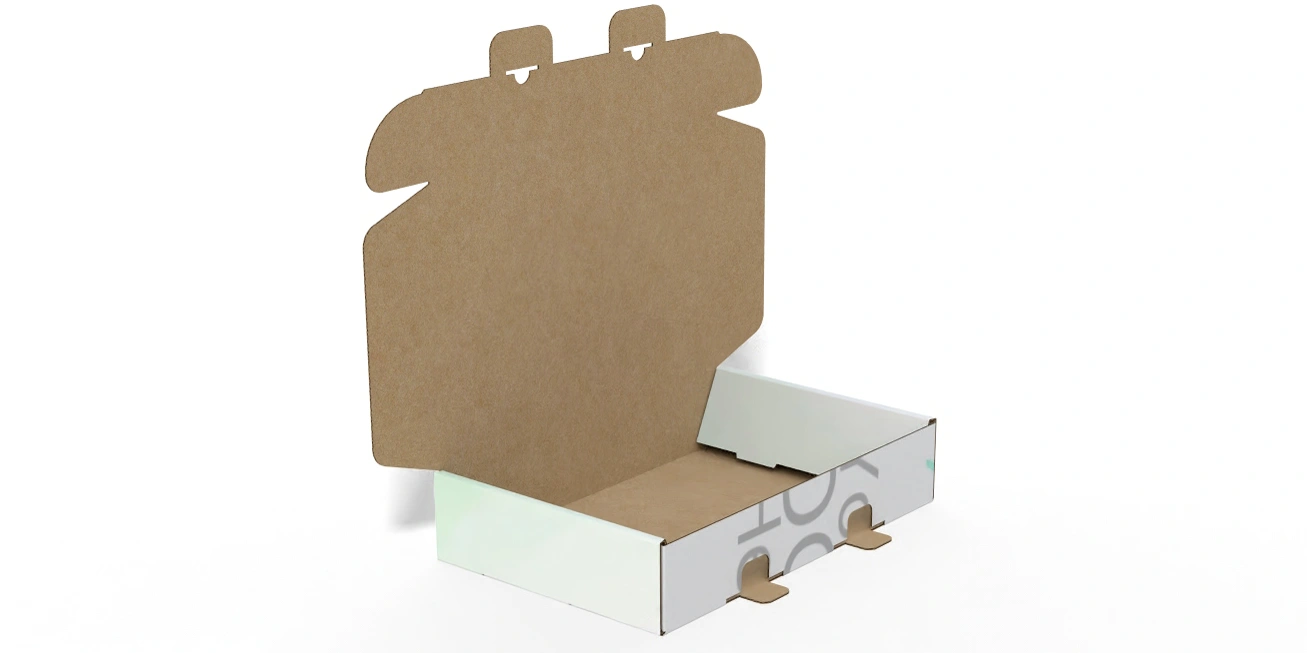

Make your packaging as unique as your brand. Our team creates corrugated packaging in various styles, sizes, and finishes, designed to fit your specific products and goals.:

Box Styles: Mailer packaging, tuck-top designs, die-cut structures, and retail display packaging

Printing: CMYK, UV spot coating, foil stamping, matte or gloss lamination

Materials: Kraft or white corrugated, single wall, double wall, or specialty grades

Add-ons: Inserts, handles, clear windows, and custom labels

Your box is more than packaging—it’s a brand statement.

Discover Corrugated Style Options for Your Brand

Discover customizable cardboard solutions designed to showcase your brand’s personality and elevate the unboxing experience.

- Materials

- Printing technology

- Printing ink

Black cardboard paper

Black cardboard paper is a dense, sturdy paperboard with a deep black color, ideal for premium packaging, custom boxes, and luxury printing projects. Its strength and rich appearance make it perfect for high-end product packaging and presentation materials.

Kraft paper

Kraft paper is a sturdy, durable material made from unbleached wood pulp, naturally brown in color. Valued for its tear resistance and strength, it’s commonly used for paper creations, shopping bags, and wrapping materials. Eco-friendly and versatile, it remains a preferred choice for bespoke paper solutions.

Specialty paper

Specialty paper refers to unique, high-quality paper designed for luxury printing, invitations, high-end packaging, and art projects. It offers distinct textures, finishes, and surface effects, allowing brands to create exclusive and premium packaging experiences.

Corrugated paper

Corrugated paper is made by bonding a fluted layer (corrugating medium) between two flat linerboards, creating a strong, durable, and cushioned material. It is ideal for shipping boxes, protective packaging, and custom corrugated packaging solutions, providing both strength and product protection.

White kraft paper

White kraft paper is a durable and versatile paper made from wood pulp, featuring a natural, crisp white finish. Perfect for wrapping, folding designs, and premium paper products, it blends strength with a refined, upscale appearance.

White cardboard paper

White cardboard paper is a thick, durable paperboard commonly used for printing, packaging, and custom boxes. Available in matte and glossy finishes, it provides a premium appearance for product packaging, retail displays, and promotional materials.

Gold Hot stamping

Foil stamping is a printing technique that uses heat and pressure to apply metallic or pigmented foil onto a surface, creating a shiny, raised design.

Silver Foil

Silver foil stamping is a printing technique that applies a metallic silver foil to a surface using heat and pressure. This process creates a shiny, reflective finish, adding a sophisticated and elegant touch to printed materials.

Embossed

Embossed logo printing is a technique where a design or logo is raised above the surface of the material, creating a three-dimensional effect..

Pressure Texture

Pressure texture printing is a technique that uses pressure to create raised or recessed textures on a surface, often without the use of ink.

Spot UV

Spot UV printing is a finishing technique that applies a glossy, shiny coating to specific areas of a printed piece, creating a contrast with the matte background.

Debossed

Debossed logo printing is a technique where a design or logo is pressed into the material, creating a recessed or sunken effect. This process is achieved by applying pressure to the substrate, without ink, to create a tactile indentation.

CMYK

CMYK paper box printing is a process used to print full-color designs on paperboard packaging using the four primary ink colors: Cyan, Magenta, Yellow, and Key/Black. This method allows for vibrant, detailed, and high-quality graphics to be printed on boxes, making them ideal for product packaging. The CMYK process works by blending these colors in varying amounts to create a wide spectrum of hues, ensuring accurate reproduction of images and designs on packaging materials. It is commonly used for retail boxes, shipping boxes, and promotional packaging.

PANTONE

Pantone color paper box printing uses the Pantone Matching System (PMS) to produce precise, consistent colors for packaging. Unlike CMYK, which mixes four inks to create colors, Pantone printing uses specific pre-mixed inks to achieve exact shades. This method is ideal for brands that require exact color matching, such as logos and corporate colors. Pantone color printing on paper boxes ensures vibrant, consistent results across different print runs, making it popular for high-end packaging, luxury products, and branding materials.

Add Your Heading Text Here

Corrugated Solutions for Every Industry

Our custom corrugated materials serve a wide range of industries, providing tailored solutions for every product type.

Electronics: Shock-resistant structures for safe product transport

Food & Beverage: Hygienic and protective corrugated cartons for delivery and retail

Cosmetics & Skincare: Sleek printed containers that enhance retail appeal

Fashion & Lifestyle: Custom mailers that elevate your unboxing experience

Whether it’s retail display or wholesale shipping, we create custom solutions that align with your brand identity.

Custom Corrugated Solutions Durable, Branded, and Made for Your Products

Material Options

Our single-wall, double-wall, and triple-wall corrugated boxes let you customize the packaging strength to protect your products and ensure safe shipping.

Premium Finishes

Enhance your custom packaging boxes with matte, gloss, or specialty coatings to create a luxury, professional look that strengthens your brand presence.

Perfect Fit

Custom packaging boxes tailored to your products, protecting items during transit while optimizing space for cost-effective shipping.

Eco-Friendly Choices

Use eco-friendly packaging materials like recycled paper and biodegradable adhesives to create sustainable custom packaging that supports your environmental goals.

Why Choose Lucklin for Custom Corrugated Solutions

LucklinPak offers fully customizable corrugated products in various sizes, thicknesses, and premium finishes. Made from eco-friendly, recycled, and FSC-certified materials, our corrugated materials meet strict international standards. With high production capacity, we ensure fast, reliable delivery, affordable pricing, and tailored solutions that protect your products and elevate your brand.

Frequently Asked Questions

Corrugated materials are widely used for protecting and shipping various products, particularly those that require long-distance transport and extra protection. Common uses include:

Electronics (e.g., phones, televisions)

Food and Beverages (e.g., chocolates, beverage bottles)

Household Items (e.g., furniture, appliances)

Textiles (e.g., clothing, shoes)

Cosmetics and Health Products (e.g., small items)

Cardboard cartons are made from a single thick layer of paperboard and are typically used for lightweight packaging, such as cereal or shoeboxes. In contrast, corrugated cartons have three layers—a wavy middle layer sandwiched between two flat layers—providing extra strength and durability. This makes corrugated cartons ideal for shipping heavier or fragile items, offering better protection against impact and moisture.

Our minimum order quantity (MOQ) for corrugated packaging is 500 units. To maximize the value of your order, we suggest placing larger orders, which will help reduce the cost per unit.

We provide various styles of corrugated boxes, including:

- Single-wall corrugated boxes: Suitable for lightweight items.

- Double-wall corrugated boxes: Used for medium-weight products.

- Triple-wall corrugated boxes: Ideal for heavy or fragile items.

- Specially designed boxes: Such as those with insert protection structures or collapsible designs.

- Custom boxes: Tailored to customer specifications regarding size, printing, and shape.

Yes, corrugated boxes are made from recyclable paperboard and are environmentally friendly. Most corrugated boxes can be reused in recycling systems, helping to reduce resource waste and environmental pollution.

The production lead time for custom printed corrugated cartons typically ranges from 10 to 15 business days, depending on the complexity of the design, order volume, and printing requirements. If the situation is urgent, you can discuss expediting the process with the supplier.

Yes, we offer sample services. You can choose different types of box samples based on your needs to help make your decision. Standard samples are usually free; however, custom printed samples may incur a fee. Please contact us with specific requirements, and we will prepare samples for you as soon as possible.

Common coatings for corrugated boxes include:

- Water-based coatings: Eco-friendly and non-toxic, suitable for food and daily consumer goods packaging.

- UV coatings: Offer strong durability and are often used for packaging requiring high brightness and printing precision.

- Solvent-based coatings: Suitable for high printing requirements; typically used for products needing high water resistance.

What they say about us

Production and shipping were fast once we agreed on the designs and everything else. The first time was hard because we didn’t know the quality and how the final project would turn out. Thank God, I love my custom creations! Jojo, who is the person I always chat with, is always kind and helpful. My best wishes to all the team who made this beautiful job, and I definitely recommend this company.

Packaging Buyer

I am so happy with my custom-made and hot-stamped candle and soap creations. The quality is exactly what I was hoping for. I will definitely be ordering from here again. I would like to thank Serena for all of her fabulous help. She was so kind and patient while offering wonderful customer service and suggestions

Manager

I am so happy with my custom-made and hot-stamped candle and soap creations. The quality is exactly what I was hoping for. I will definitely be ordering from here again. I would like to thank Serena for all of her fabulous help. She was so kind and patient while offering wonderful customer service and suggestions.

Global Sourcing Manager

Transform Your Unboxing Experience with Custom Corrugated Designs

Partner with Us for Expert Design and High-Quality Production. Contact Us Today!