The Soul of Packaging Begins with Printing

When you’re ready to create custom paper bags or paper boxes for your brand, you probably first think about materials, structure, or design. Of course, those are all important — but what truly brings your packaging to life, what really makes your brand stand out, is printing.

Imagine this: your logo and artwork are beautifully designed, but if the printed colors are off, the image looks blurry, or the ink fades easily, all that effort could go to waste. Printing is what gives packaging its soul.

It influences far more than just appearance — it determines:

- First impressions: the visual and tactile experience your customers have when receiving your packaging.

- Color consistency: how accurately and reliably your brand colors appear.

- Perceived value: high-quality printing instantly makes packaging look more premium, enhancing the product’s worth.

In this guide, we’ll walk you through the most common printing methods and finishing techniques used for paper bags and boxes — explained in simple terms, without jargon. By the end, you’ll know exactly how to choose the printing solution that best fits your brand and makes your packaging truly shine.

Why Printing Matters So Much in Custom Packaging

In today’s competitive market, your packaging is essentially your silent salesperson — and printing determines how that salesperson “dresses” and “speaks.” It shapes the first impression of your brand’s professionalism and quality.

1. Printing Is Your Brand’s Visual Language

A great print job helps your packaging catch attention at first glance.

- A gold-foil logo communicates luxury and craftsmanship.

- Eco-friendly inks and natural tones express your brand’s sustainability values.

Printing isn’t just about colors and graphics — it’s your way of telling your brand story through visuals.

2. It Elevates Product Perception

Think about the feeling when you hold a well-printed, soft-touch packaging box — it immediately feels premium and trustworthy.That’s the psychological power of quality printing. It boosts perceived value and makes customers feel your product is worth more.

3. It’s the Carrier of Your Brand Story

Whether it’s a festive edition, seasonal theme, or minimalist design, printing brings personality to your packaging.Customers aren’t just seeing your box — they’re connecting with your brand philosophy and style through it.

Let’s compare:

✘ Poor printing or blank packaging: forgettable, lacks brand presence.

✔ High-quality printing: looks like a piece of art, photo-worthy, shareable — and drives organic exposure and sales.

Common Printing Methods Explained — Find Your Perfect Match

There are many ways to print, but when it comes to custom paper packaging, four main methods dominate. Let’s break them down simply so you can choose what fits your brand best.

1. Offset Printing

Offset printing is a bit like the DSLR camera of printing — super clear, detailed, and great for big projects. It works by layering ink through rollers and plates, which gives you smooth colors and sharp images. The result looks professional and consistent, perfect if you want your packaging to feel high-end.

The only downside is that it costs more to set up because it needs printing plates, so it’s better for larger orders. If you’re making luxury gift boxes, cosmetic packaging, or fashion paper bags, offset printing is a really good choice for getting rich colors and a premium look.

2. Digital Printing

Digital printing is like a high-end office printer — fast, flexible, and ideal for small orders. It doesn’t need any printing plates; your design files go straight from the computer to the printer, which makes it quick and easy to get started. It’s perfect for small-batch packaging, prototypes, or test runs, and you can even personalize each piece with names, QR codes, or unique artwork.

The only trade-off is that the colors might not be quite as consistent as offset printing, and if you print a lot, the cost per unit can be higher. It’s a great option for e-commerce packaging, promotional boxes, or seasonal limited-edition paper bags where flexibility and customization matter most.

3. Screen Printing

Screen printing feels a lot like handmade art — the prints are thick, textured, and full of character. The process works by pushing ink through a mesh stencil onto the paper, which gives the design a vibrant, tactile feel. It’s also very durable and can be used on all kinds of materials, not just paper, but also fabric or even wood.

The downside is that it’s not great for designs with lots of gradients or complicated details, and it’s a bit slower to produce. It’s perfect for minimalist designs, handcrafted packaging, canvas tote bags, or eco-friendly paper bags where you want that extra touch of texture and personality.

4. Flexographic Printing

Flexographic printing is the fast and eco-friendly choice, perfect for everyday packaging. It uses flexible resin plates and water-based inks, which allows for high-speed printing while being gentle on the environment. This method is super efficient and cost-effective, especially when you need to produce large quantities.

The main limitation is that it can’t capture very fine details or complex color gradients. It works best for takeaway paper bags, food boxes, corrugated shipping boxes, and other large-volume retail packaging where speed, affordability, and sustainability are important.

Finishing Touches — Giving Your Packaging Its Final Glow

Printing is your packaging’s foundation, but finishing techniques are its “makeup.” These add texture, luxury, and durability to make your packaging stand out.

1. Foil Stamping (Hot Stamping)

Foil stamping, also called hot stamping, gives your packaging that shiny, metallic touch in gold, silver, rose gold, or even holographic colors. It’s perfect for making logos, borders, taglines, or luxury retail packaging really stand out and look premium.

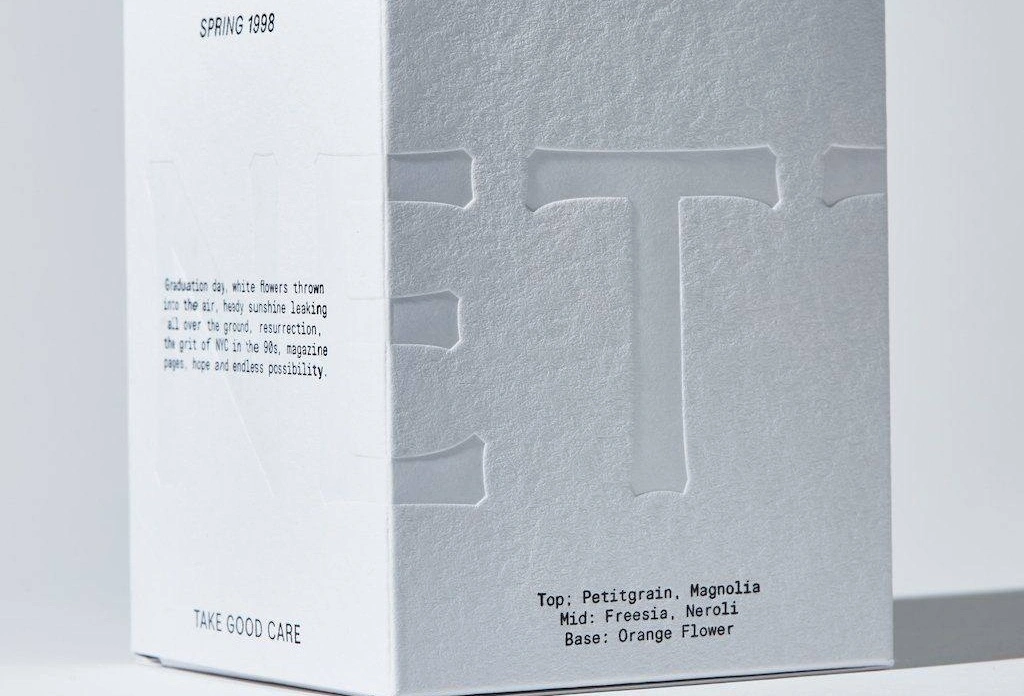

2. Embossing / Debossing

Embossing and debossing add a tactile, 3D effect to your packaging by pressing the paper to create raised or recessed designs. It’s a subtle but elegant way to make logos, brand names, or minimalist designs feel more sophisticated and premium.

3. UV Coating

UV coating adds a glossy or matte finish to your packaging, protecting it while making certain areas stand out. It’s great for highlighting logos or intricate design details and giving your packaging a polished, professional look.

4. Lamination

Lamination puts a thin protective film over your printed packaging to make it look and feel better. Glossy lamination makes colors pop and shine, while matte lamination gives a smooth, elegant, and fingerprint-resistant finish. It’s perfect for shopping bags, retail packaging, and luxury gift boxes.

How to Choose the Right Printing & Finishing for Your Brand

Choosing the right printing and finishing for your packaging really depends on your brand style, budget, and what your customers expect. If you want premium quality with precise colors, offset printing is the way to go.

If you’re doing small batches or need flexibility, digital printing is perfect. For a handcrafted, textured feel, screen printing or adding embossing and foil effects can give your packaging that extra touch of personality.

For high-volume, cost-effective projects, flexographic printing works best. And when it comes to finishing, if you want a luxury, eye-catching look, try combining foil stamping with spot UV. If you prefer something subtle and elegant, matte lamination with a debossed logo is a great choice.

Conclusion: Printing Brings Your Brand to Life

Printing is more than just putting ink on paper — it’s how your brand speaks visually to your customers.

The right printing method and finishing technique can transform your packaging into a story, a statement, and a memorable experience.

If you’re unsure which option fits best, Lucklin Packaging is here to help.Our expert team can recommend the perfect printing and finishing combination for your custom paper bags and paper boxes, based on your product, budget, and brand goals.

✨ Let your packaging be more than just beautiful —Let it speak your brand’s story.